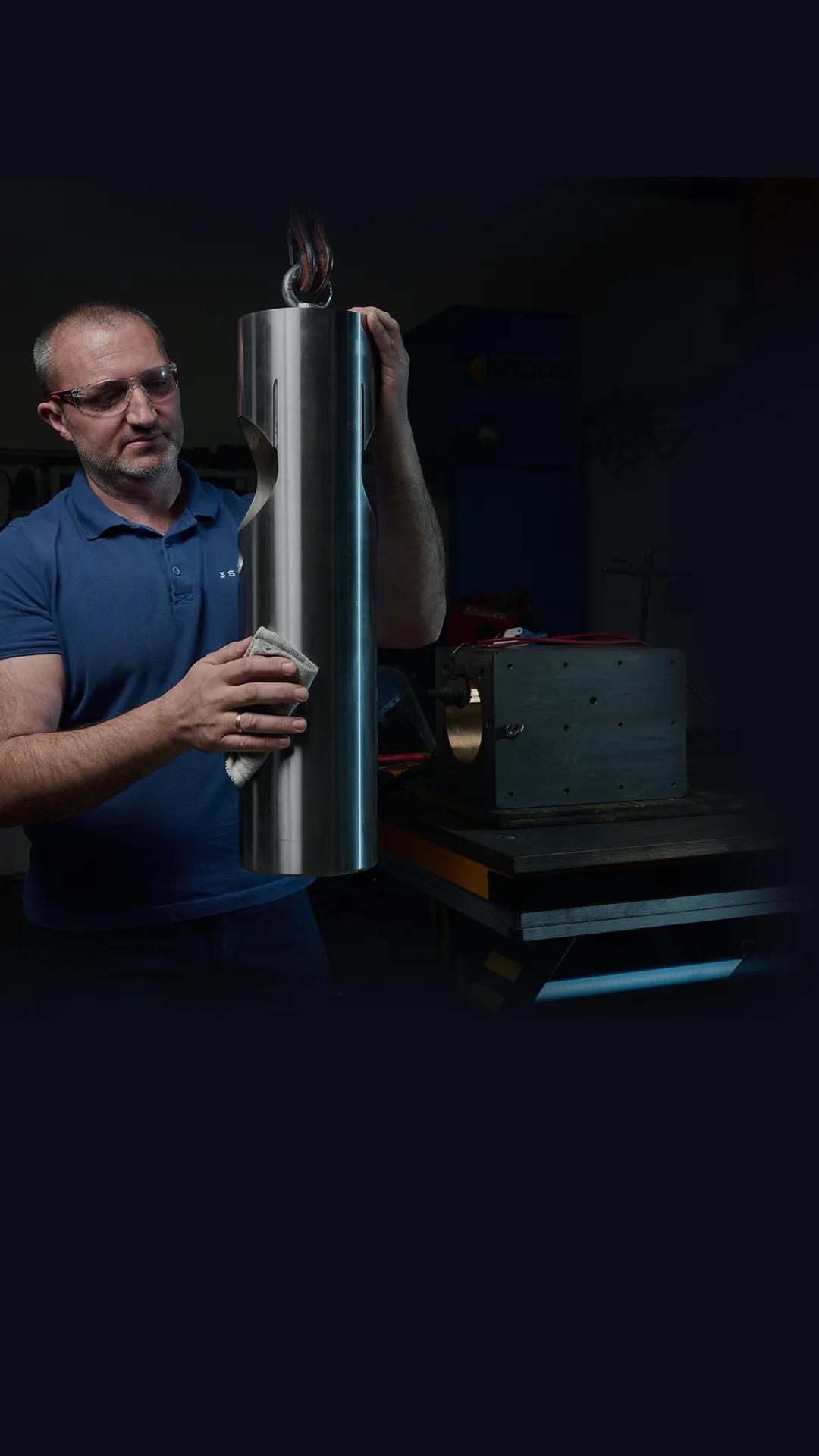

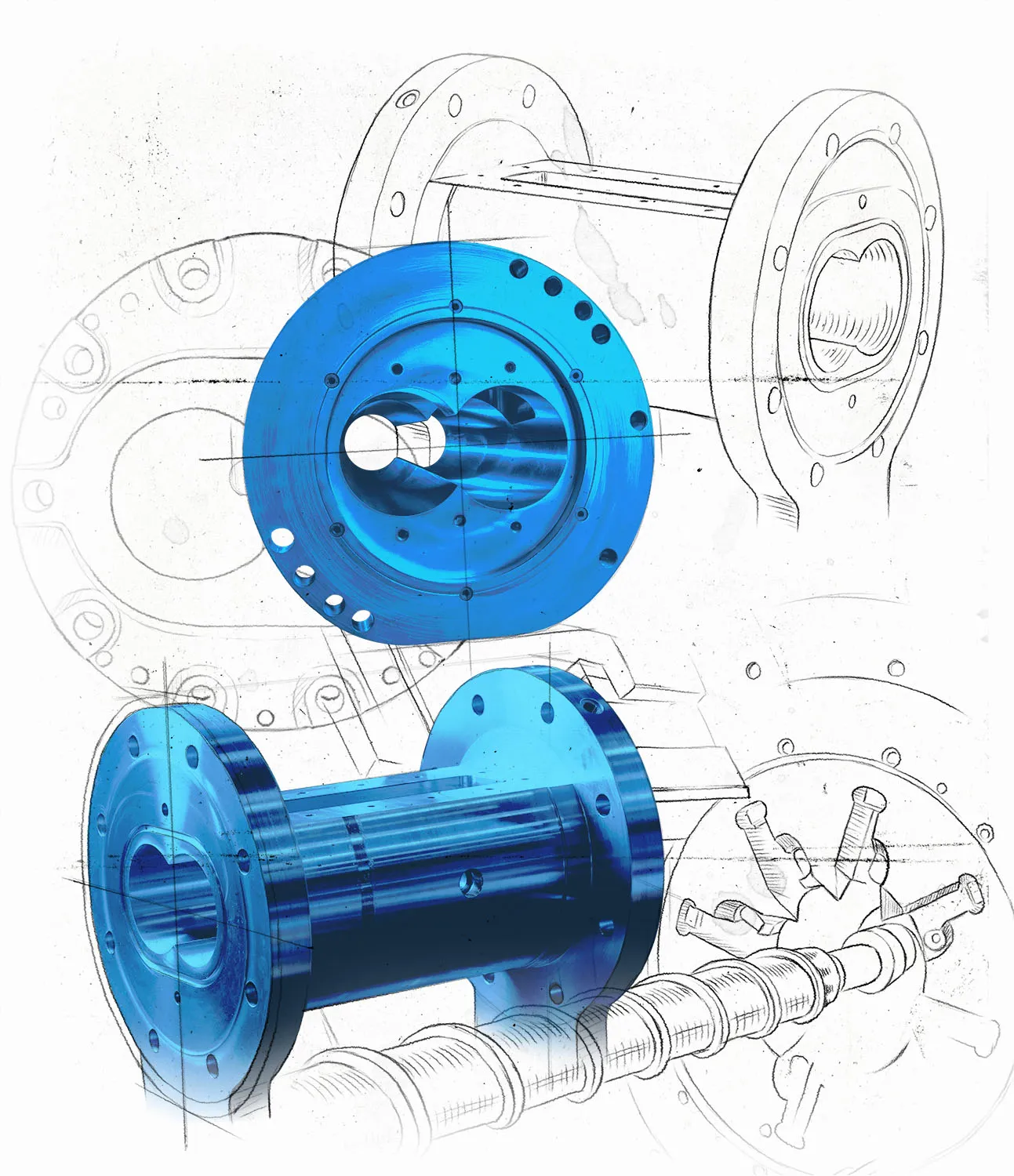

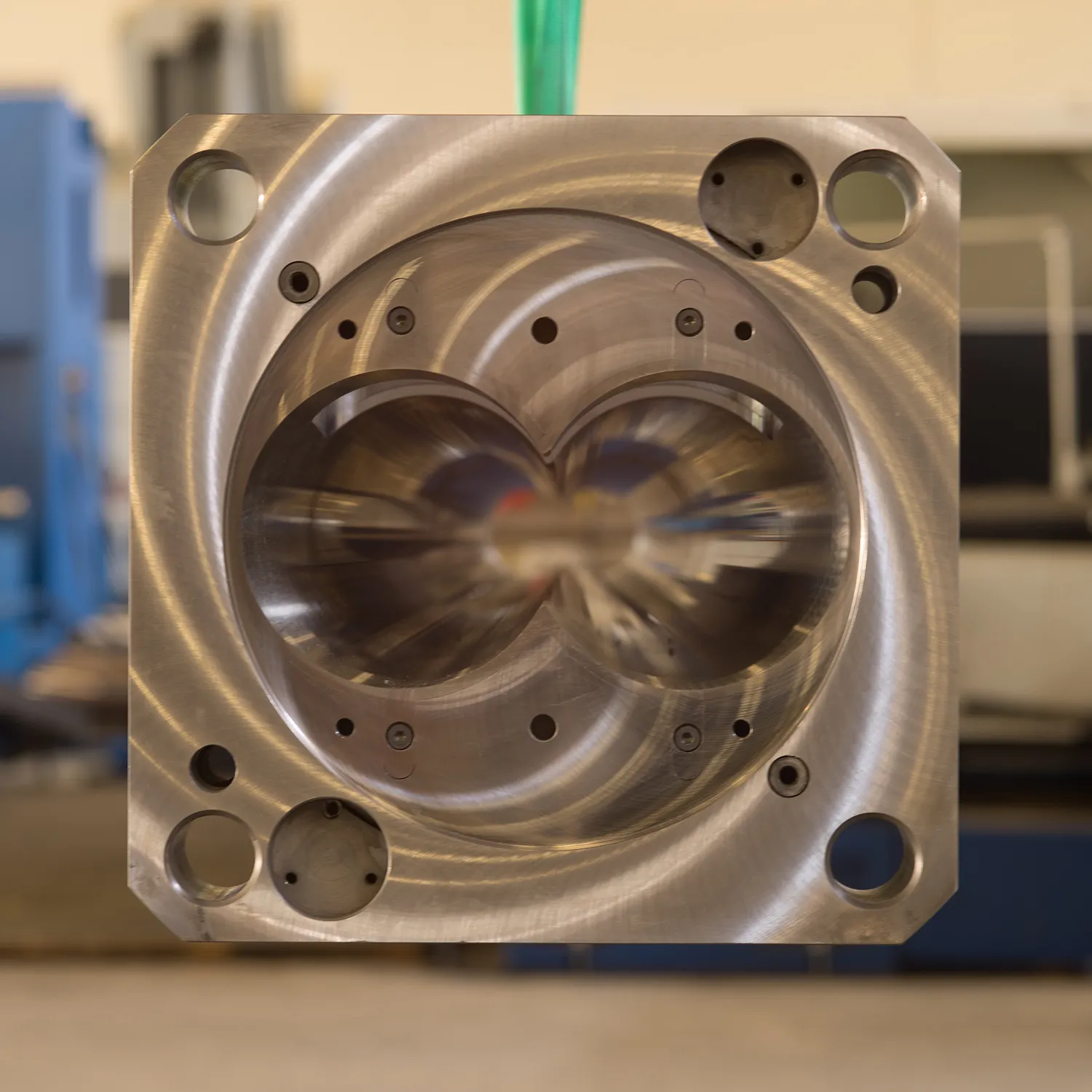

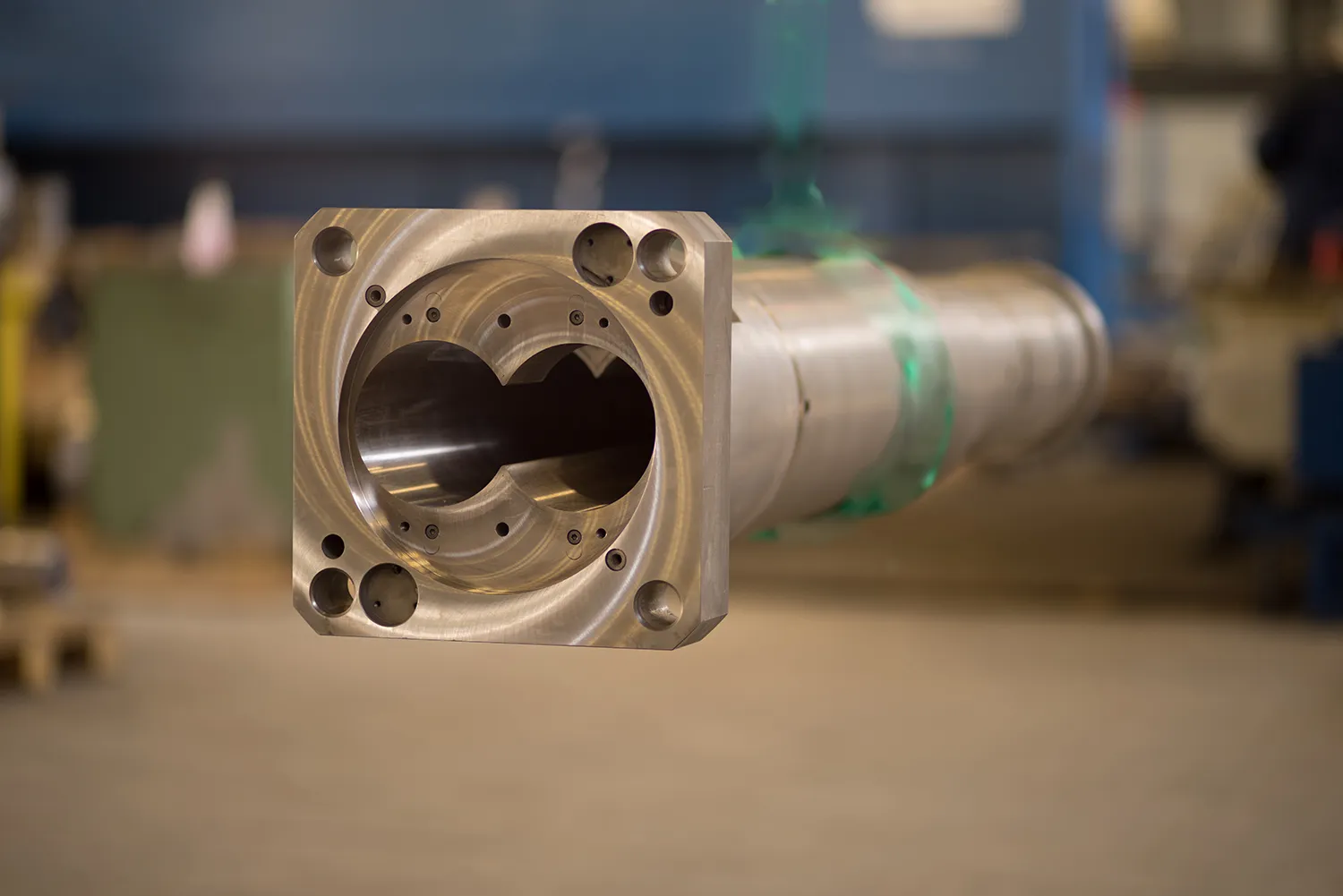

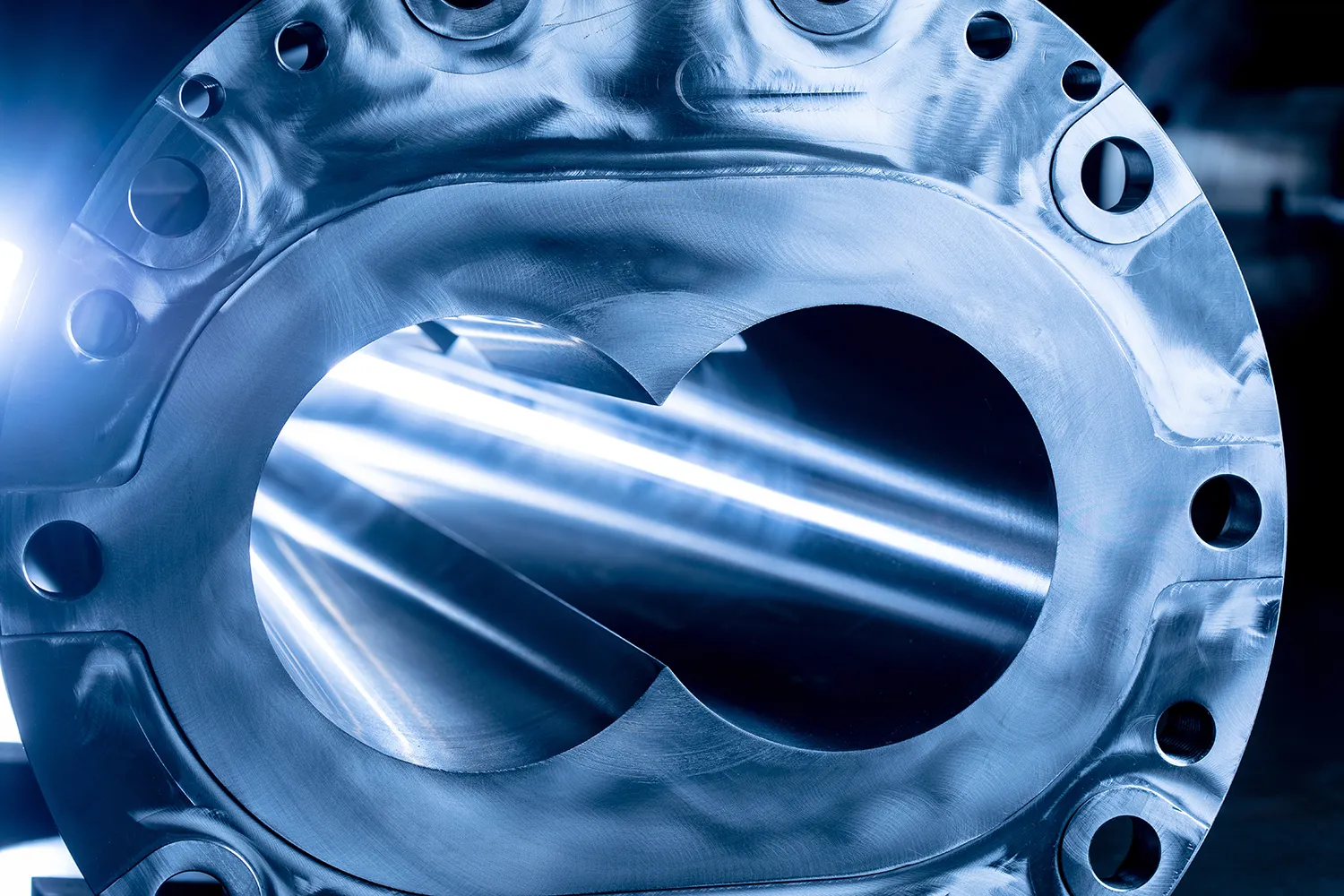

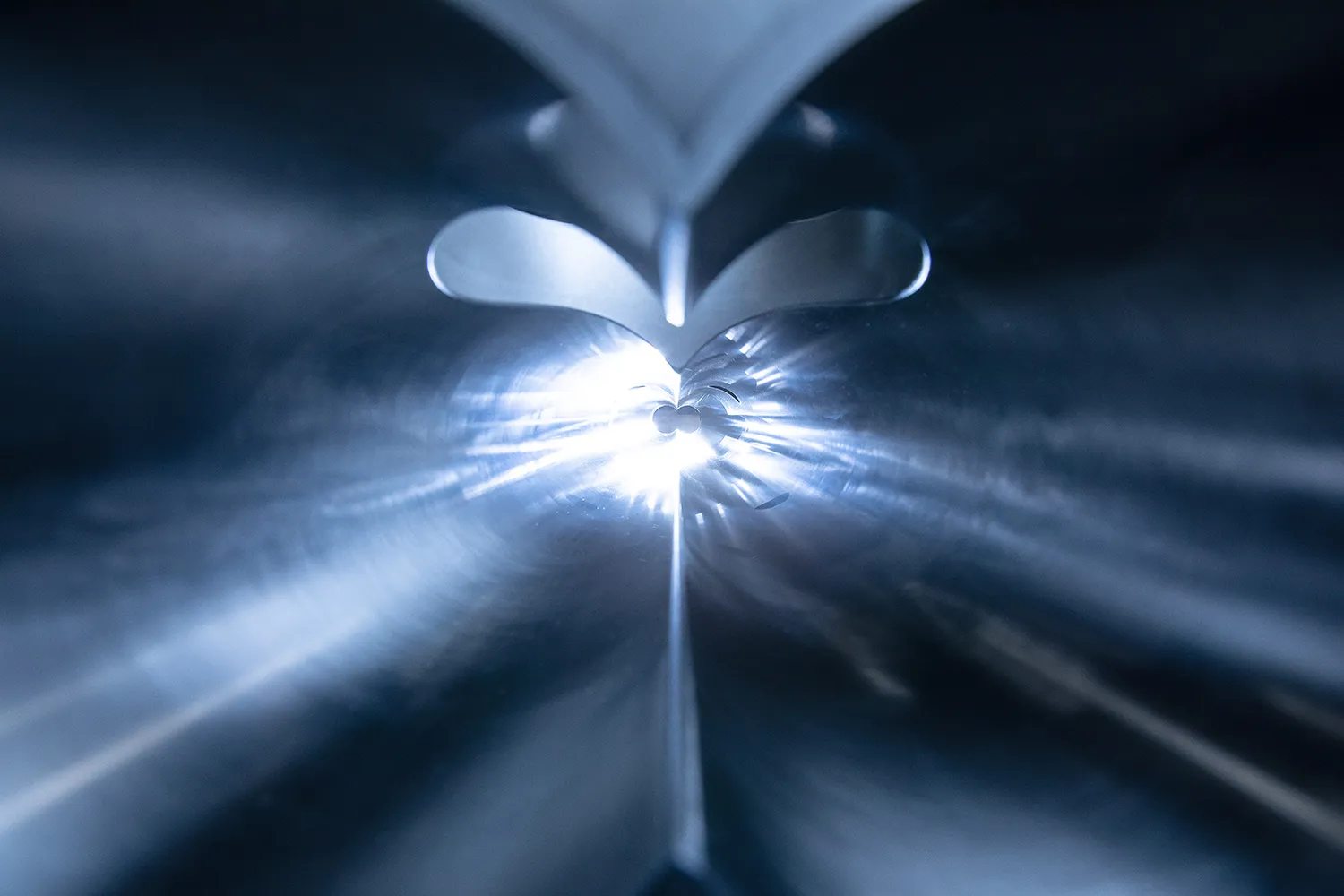

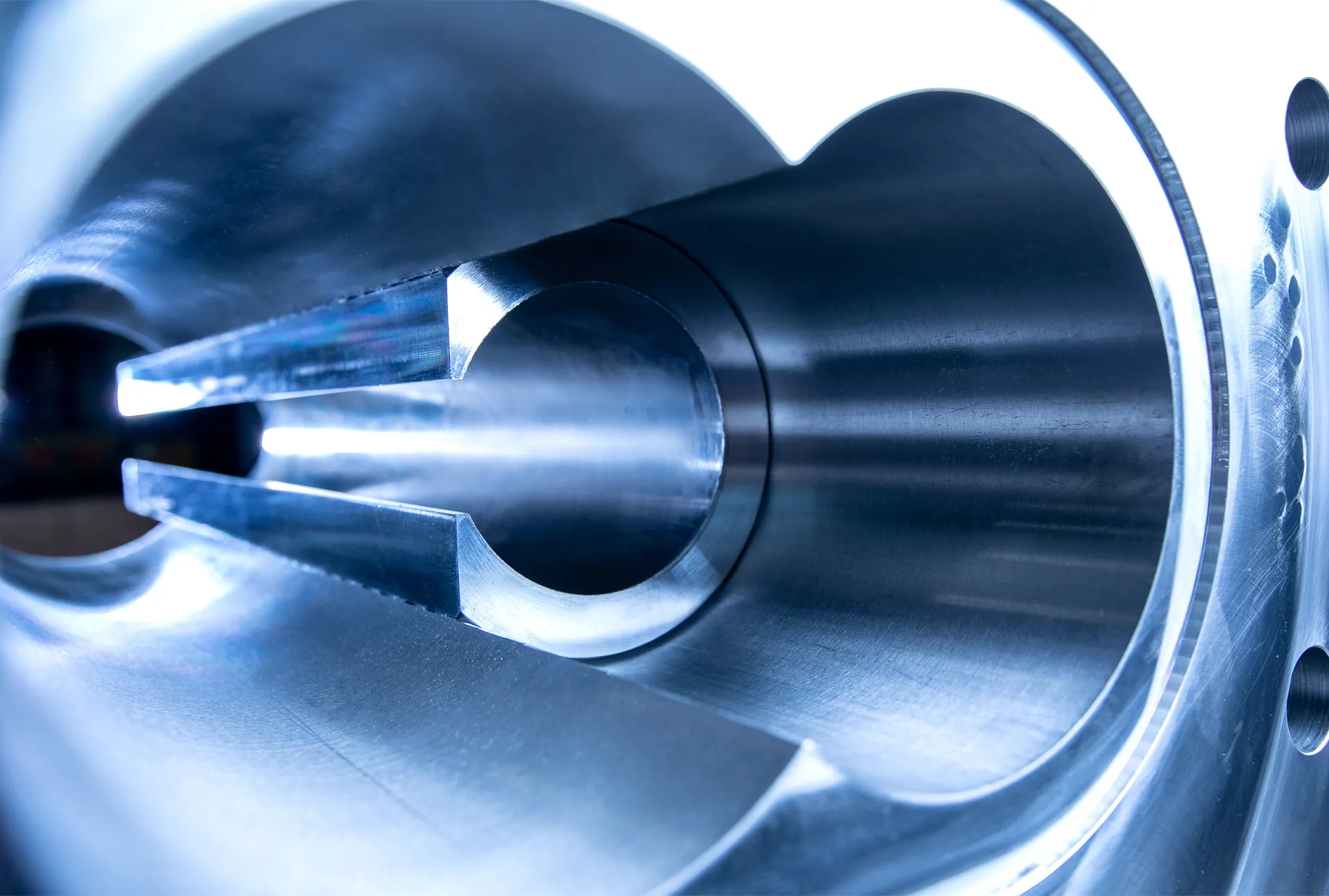

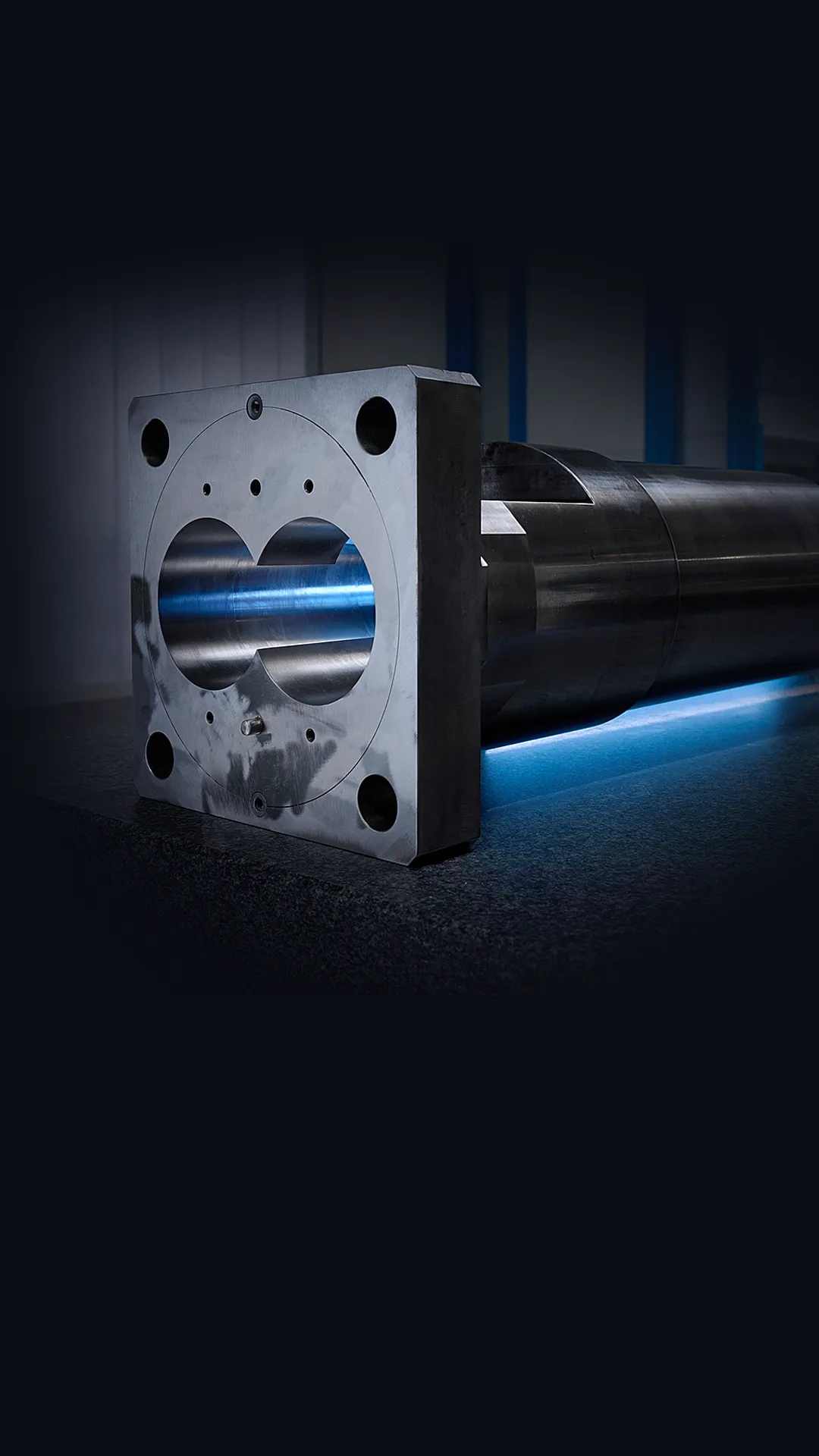

Barrels with a longer service life

3S invented the wear-resistant sleeve.

Barrels with a longer service life

3S invented the wear-resistant sleeve.

Barrels with a longer service life

3S invented the wear-resistant sleeve.