Protected against the toughest wear

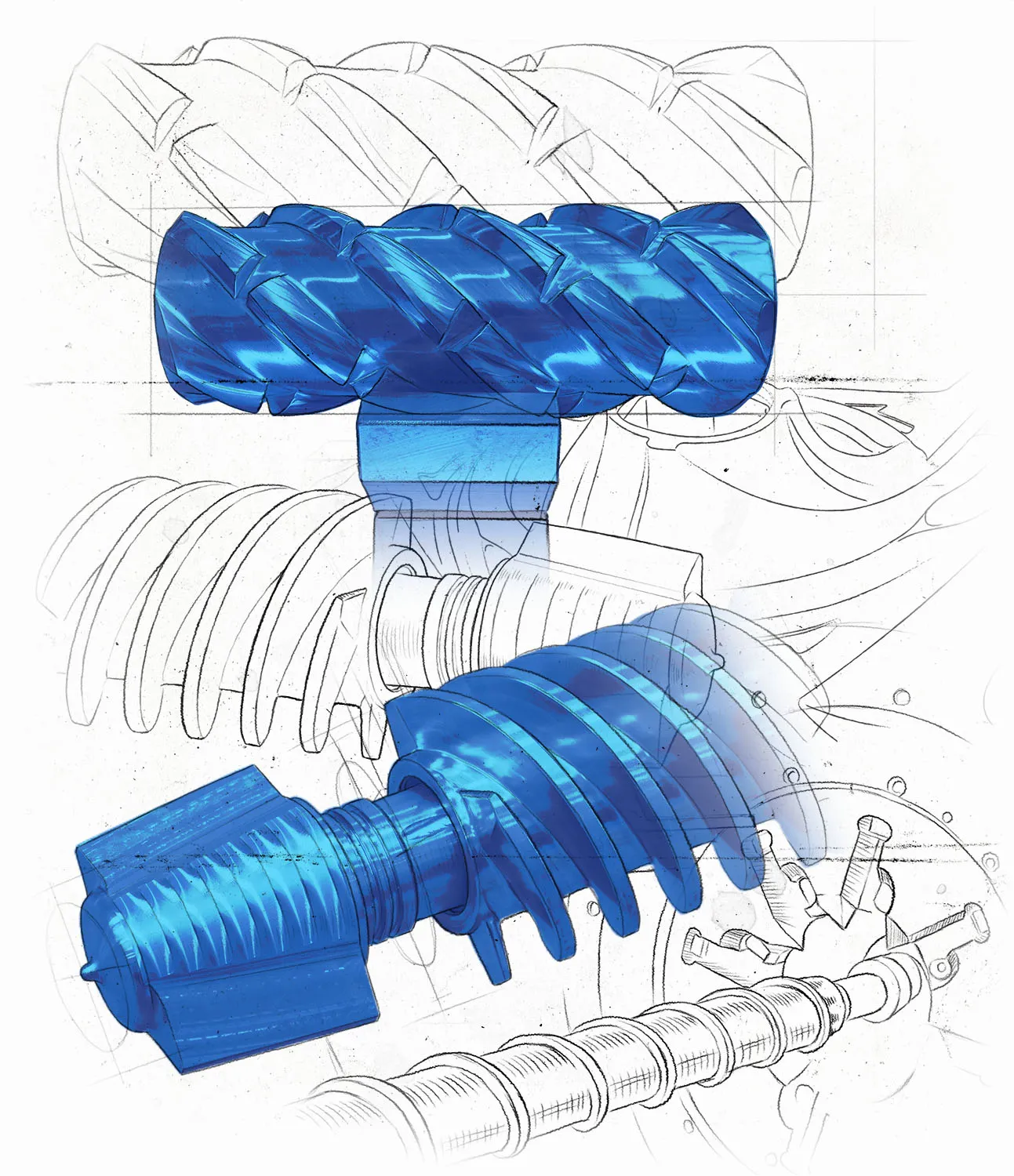

We focus on your specific requirements. Our single screws and twin screws are exactly matched precision parts. Conical and cylindrical. Co-rotating and counter-rotating. Ultimately wear resistant for every application.

Your advantages in a nutshell:

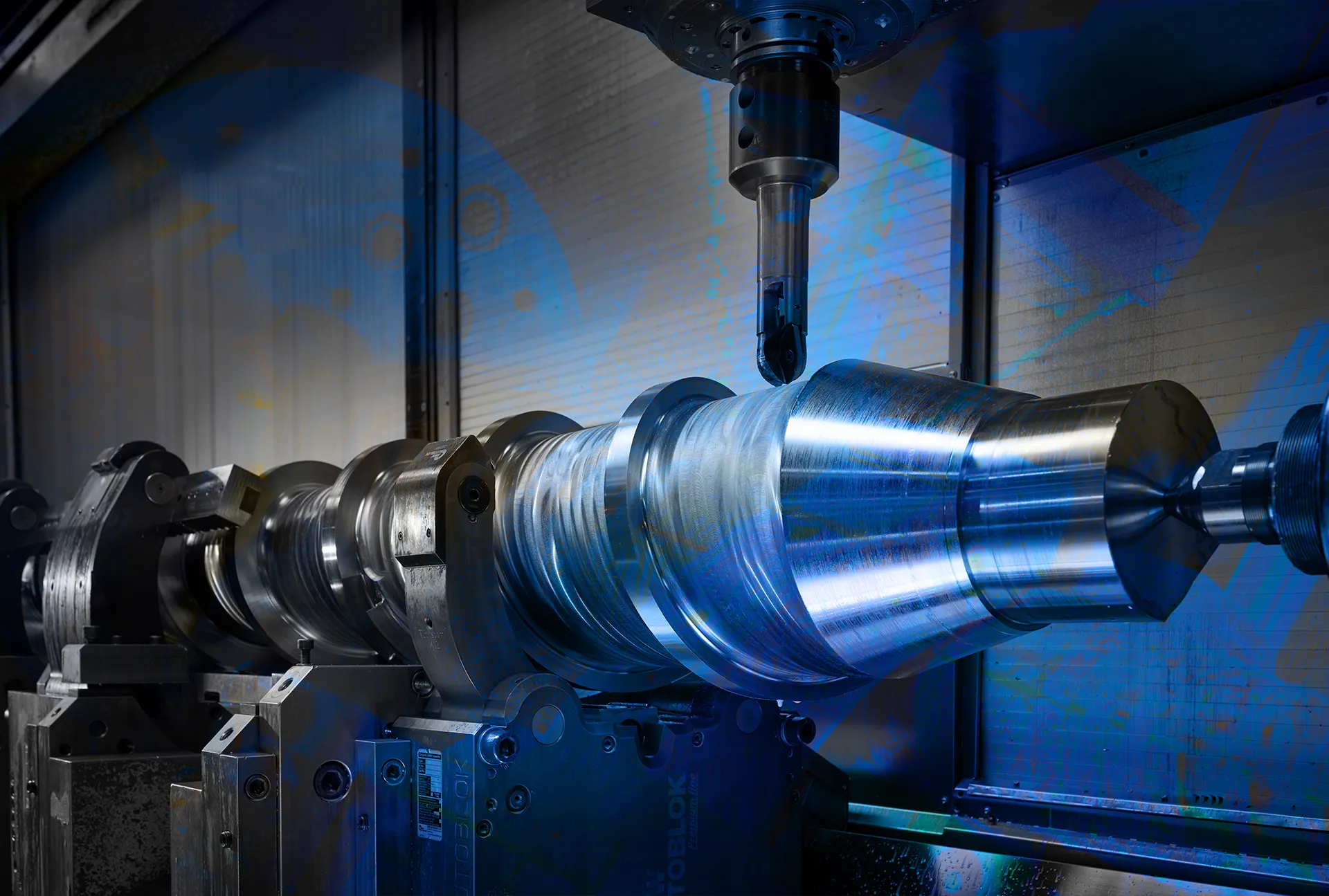

3S makes screws for extrusion and injection moulding. Up to a length of 6500 mm and a diameter of 500 mm. Single and multiple sections. In various designs. For all extrusion applications:

Screw accessories such as parts for mixing and shearing, screw tips and non-return valves are also part of the wide 3S product range.

Your advantages in a nutshell:

Twin screws - co-rotating and counter-rotating - are manufactured in a cylindrical or conical design. Molybdenum-coated screws and screws armoured with a CNC plasma welding system offer alternatives to nitrided screws in terms of wear protection.

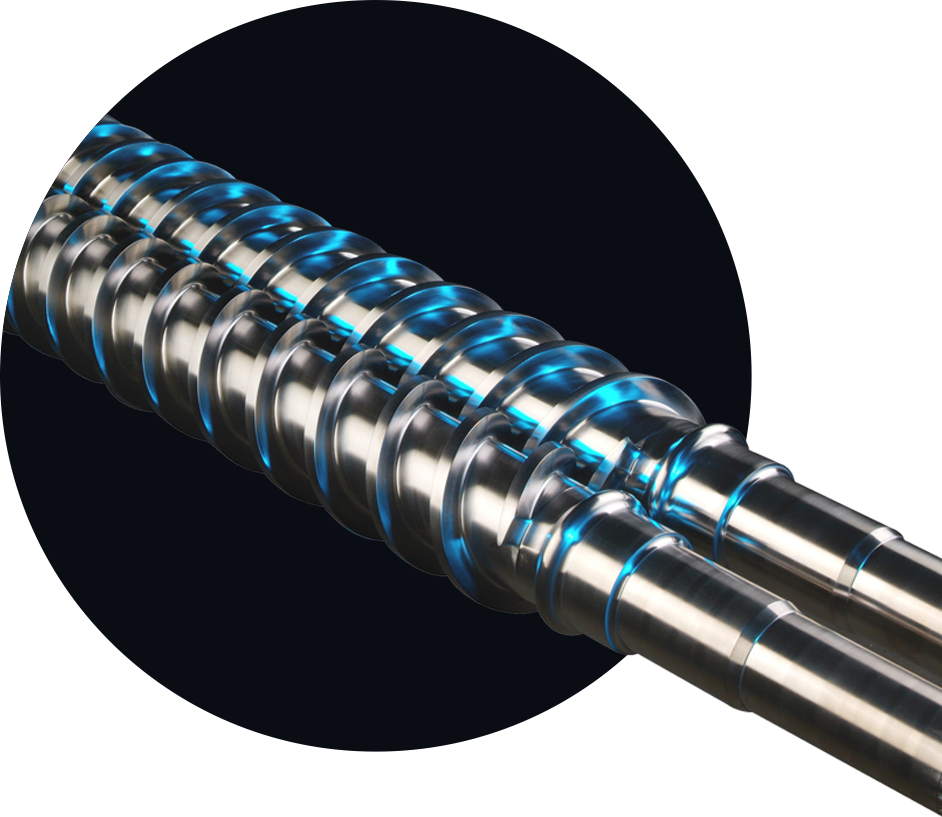

LASER ARMOURED SCREWS FOR EXTRUSION

To date, state-of-the-art technology for armouring extruder screws has involved deposition welding processes such as TIG (Tungsten Inert Gas) or PTA (Plasma Transfer Arc) in which the welding material is applied in powder form. A closely-associated process is laser CMB (Controlled Metal Buildup). This process uses a laser beam to melt the weld material instead of using an electric arc or plasma.

Working closely together with a research institute, 3S has developed a laser CMB process for extruder screws. This process can be used to armour screws between 1 and 6 metres long and 50 to 500 mm in diameter.